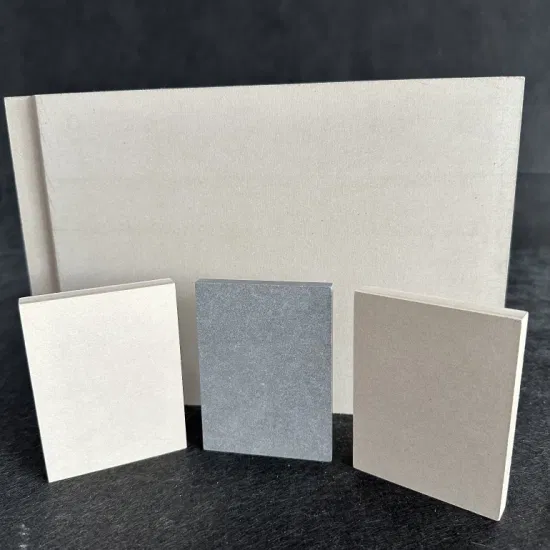

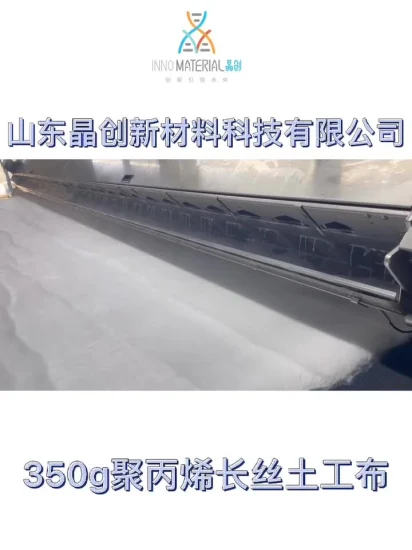

Chinese Manufacture High Quality Polypropylene PP Polyster Pet Needle Punched Non Woven Geotextile Price

Basic Info.

| Model NO. | ASTM |

| Material | PET |

| Brand | Inno |

| More Color | Green Black Yellow White |

| Other Material | PP Pet |

| Length | Customized |

| Width | 1-6m |

| Transport Package | Woven Geotextile +Paper Rolls |

| Specification | Customized |

| Trademark | INNO |

| Origin | China |

| HS Code | 5602100000 |

| Production Capacity | 50000sqm/Per Day Depends on The Specification |

Product Description

PP staple needled punched nonwoven geotextile is produced with PP staple fiber as the main raw material. It has the functions of isolation, filtration, drainage, reinforcement, protection and maintenance.O Product specification80g~1200g; 1 ~6m in width, and the length is according to the customer's demand. Product featuresIt has good flexibility, good water permeability, excellent performance of filtration, drainage, isolation and enhancement, and is convenient for construction.

| Weight | 100-1200g or As your request |

| Width | Within 1-6m as your request |

| Length | 50-400m or As your request |

| Material | PET |

| Color | Black, White, Green, Gray or as your request |

| Type | Nonwoven;Short or Long Fiber |

| Package | Double layers white woven geotextile; or As your request |

| Shipping Marks | As your request or Neutral Packing |

| Production Standards | ASTM, GB, or As your request |

Application scope

(1). Water conservancy project and hydropower project.

(2). Road paving , railway.

(3). Airport and port.

(4). River bank protection and tunnel.

(5). Environmental protection.

How to install geotextile fabric

Let us show you how easy the installation is and provide a few useful tips along the way. In our example,

Step 1 - Prep the road surface

First, you will need to excavate the roadway to the desired elevation. Then fully compact your subgrade, making sure you have removed all air and tightened the soil completely.Step 2 - Unroll the reinforcement geotextile fabric

Roll the geotextile fabric on the compacted subgrade, making sure it's free of wrinkles and folds. Overlap your fabric as directed by the engineer. Cherokee can pre-sew the fabric for you if a stitch seam is required. Contact your Cherokee representative to get pricing on factory seamed rolls in a wider widths.Step 3 - Sew the geotextile fabric

This job required the fabric to be stitched on the job site. The fabric needs to be seamed with a dual thread lock stitch to prevent it from unthreading. We have equipment available for purchase or rental to do the stitching on the job. At the engineers discretion you can choose a prayer seam, j-seam, or butterfly seam. In this example we will be using a j-seam. We recommend doing two stitches on each seam to prevent any failure during installation.Step 4 - Apply Aggregate

Place your aggregate to the specified thickness, ensuring that no equipment drives directly on the engineered fill. Make sure the fill has reached full compaction before the final step.Step 5 - Lay Asphalt

Now that you have placed your subbase you are ready for your pavement layer (or layers depending on the project type).

Packages and Shipment

Nonwoven Geotextile is packed in the woven bags or follow your demand.Keep it away from moisture and fire!!!

Upholding the ambitious development vision. Innovative company takes the innovative cooperation as the permanent drive for the enterprise development. The company aspires to always standing in the forefront of the industry driven by a lot of efforts to closely cooperate with the international leading research institution and collages, continues to increase investment in research and development, strengthen the research team, and build the high standard experiment, technology center and testing center.

Industrial chain up and down extension, continue to develop innovative productsThere are five categories of products and 60 specifications and models, among which frontier products account for more than 50% Capacity development: five production lines have been put into operation, with an annual capacity of more than 50000 tons

Dream for a creative future!With the enterprise vision, we set sail.We are based on the high-end brand of geosynthetics worldwide, and focus on exploring and developing new geosynthetics materials that are corrosion-resistant, weather resistant, durable, uniform, environmental-friendly andsafe, to professionally provide functional basic materials for major engineering construction projects such as highway, railway, water conservancy, sponge City, landfill, aerospaceand national defense.Since the start of business, every product and technology developed has condensed our wisdom and effort; every project implemented in the development has shown our vision and progress; every commitment to our customers has delivered our confidence and sincerity! Every achievement we have realizedis owed to the support and care firomleaders, experts, partners and friends!We deeply understand only by holding fast to the development concept of "achieving stems from sharing", can we gain more valuable cooperation opportunities and see a better industrial future. Looking forward to working with you, sharing the joy of development!