Fashion False Metal Ceilings Customized Building Material Suspended Curved Aluminum Ceiling

Basic Info.

| Model NO. | TB-ceiling 064 |

| Feature | Artistic Ceilings, Integrated Ceilings, Perforated Ceilings, Linear Ceilings |

| Surface Treatment | Polyester Powder Coating |

| Surface | Flating |

| Oxidation Resistance | High |

| Installation | Steel |

| Application | Office, Hotel, Public |

| Shape | Square, Irregular, Rectangle, Strip |

| Usage | Office, Hospital, Hotel, Commercial Building |

| Ceiling Tile Type | Metal Ceilings, Aluminum Ceiling |

| Transportation | by Sea, by Air, by Train |

| Material Option | Aluminium Alloy, Galvanized Steel, Stainless Steel |

| Color | White, Grey, Silver, Wood/Stone Grain |

| Transport Package | Packed in Cartons or Plywood Boxes |

| Specification | W100/150/200/250/300mm, Customized |

| Trademark | TOPTIDE |

| Origin | China |

| HS Code | 761090 |

| Production Capacity | 360, 000 Square Meters/Year |

Product Description

Fashion False Metal Ceilings Customized Building Material Suspended Curved Aluminum Ceiling

Services

1, Free small samples;2, Provide design proposal;3, Strict inspection process;4, Supply warranty certification.

Product Description

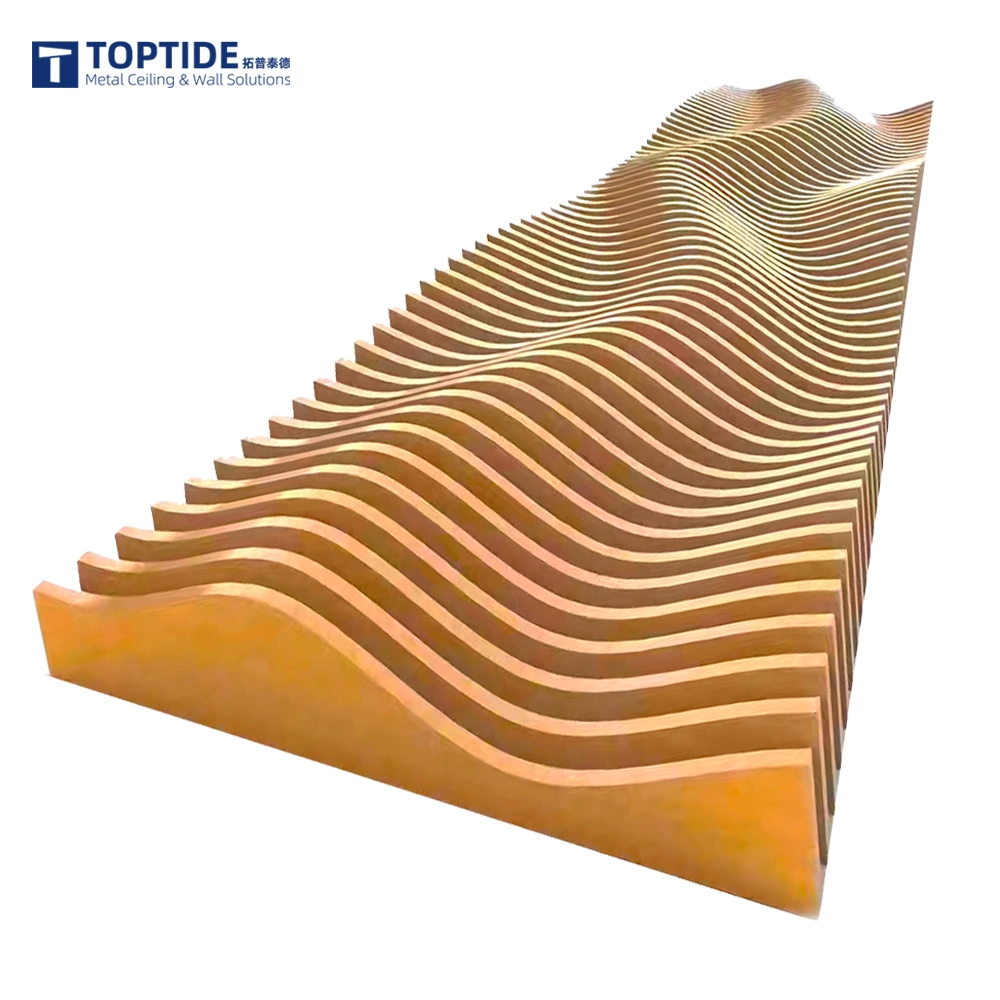

1. A curved aluminum baffle ceiling is a type of metal ceiling that is made from curved aluminum panels that are designed to create a visually striking and dynamic ceiling system. The panels are typically installed in a series of repeating baffles, or individual panels that are suspended from the ceiling structure by a series of support wires or rods.

2. The curved shape of the panels creates a sense of movement and flow, and can be used to create a variety of design patterns and configurations. The panels can be finished in a range of colors and textures, including metallic finishes, wood grain patterns, and custom colors, to suit the design preferences of the space.3. One of the advantages of a curved aluminum baffle ceiling is its ability to provide acoustic control and sound absorption, which can be particularly useful in large open spaces such as lobbies, atriums, or auditoriums. The baffles can be designed with perforations or other acoustic treatments to help reduce noise and improve sound quality.4. Another advantage of a curved aluminum baffle ceiling is its durability and low maintenance requirements. Aluminum is a lightweight material that is resistant to corrosion and weathering, making it ideal for use in high-humidity or outdoor environments. The panels can also be easily cleaned with a damp cloth or mild detergent, making them a practical choice for commercial or public spaces.

| Product Name | Curved Aluminum Baffle Ceiling |

| Materials | Aluminum Alloy |

| Thickness | 0.8-3.0mm |

| Length | ≤6000mm |

| Normal Sizes | Customized available |

| Surface Treatment | Powder Coating, PE/PVDF, Heat Transfer Printing, Interior Film, Wood Veneer |

| Main Application | Bus station, exhibition halls, supermarket, office building or residential area,railway station , Mall, Restaurant etc. |

| Shape | Strip ceiling, Baffle ceiling, Aluminum Profile, Extruded linear ceiling |

| Packaging | Carton Package |

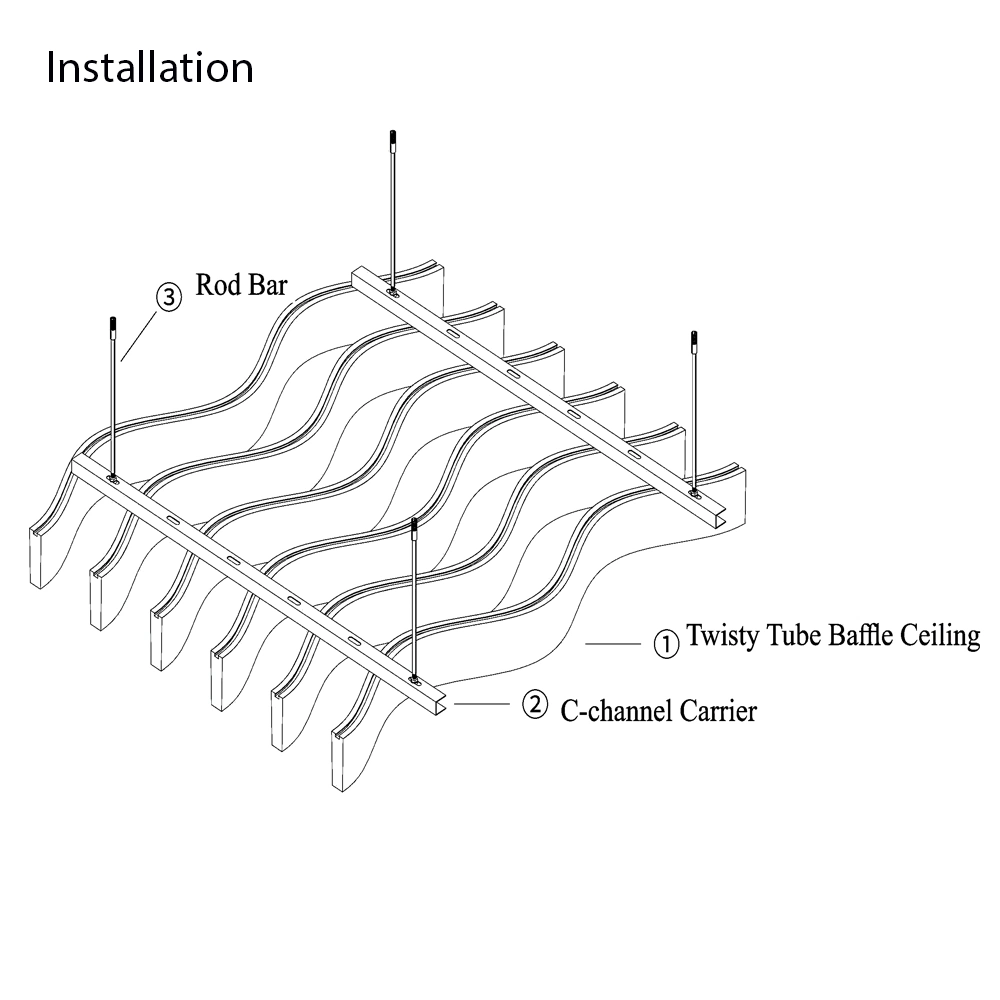

Installation Instructions

Colors

Various colors and shadows as below for choice, and customized colors are available too.(Due to printing limitation, color may vary from actual product.)

Factory Profile

Factory is covering an area of 50,000 square meters around, yearly capacity: Non-standard products are above 1 million square metersan standard products are above 2 million square meters. We have high-end machine in the world, like Italian SALVAGNINI P4X Metal Sheet Processing Equipment, Canadian IKE 7.5-Meter Numerical Control Bending Machine and British YILUDA Automatic Painting Line. With 75% high rate of production automation, we'll meet customized requirements.

Machinedis playThe world 's most sophisticated Savannini , ItalyMultilateral CNC bending equipment Lean Production.P4X system is the perfect solution for lean production equipment, simplify the production process, minimize waste and eliminate labor cost .The unmanned operating system can fully automatically produce , maximize the production efficiency .Each workpiece processing only needs18'-25' to complete.

CNC material perforated equipment

Japan Amada, Germany, Italy Canada and other countries imported.CNC production equipment . Suitable for all kinds of metal plate cutting, non-standard special- shaped plate for one time complete punching ( artpunching ), Angle cutting , full hydraulic system, low noise, computer numerical control , high processing accuracy , high production efficiency , easy to operate, can use personalized tools.Automatic Painting Line

ELETROPAINT 's equipmenthas the world 's advanced production level. Automatic control of the production process, ensure that the product coating is uniform, luster, and with high strength, resistance to twists and turns and excellent hardness, chemical resistance, etc.The quality of the products can fully meetthe American AAMA2605-98 standard, China GB /T5237.5-2000 standard.

FAQ

1, Q: Are you manufacturer or trading company?

A: We are professional manufacturer. Our brand TOPTIDE is well-known in metal ceiling & wall projects in China.Welcome to visit TOPTIDE industrial park in Guanghzou.2,Q: Do you provide design service?A: Yes. We have an architectural design team over 10 designers3,Q: Do you suply free samples ?

A: We provide free small samples for free, but express freight collect 4,Q: How to place order ?

A: Please inform us of the product types, specification and quantity, and then we'll make P/I to you. 5,Q: How do you test the product before they are packed?A : We have strict QC procedures. Each product will be tested by three times with professional machines before packing. 6,Q: What's the delivery time ?

A: Usually 15-20 days after receiving advance payment7,Q: Where is the shipping port ?

A: We ship products via Guangzhou Ports and Shenzhen Ports depend on your needs.8,Q: What about the payment terms ?

A: T/T 30% TT payment in advance, and T/T 70% balance before shipment.