Overview

Basic Info.

| Ceiling Tile Type | Width: 2m or Customized |

| Surface Treatment | Homogeneous, Reinforced, Fleece Backed |

| Function | Waterproof |

| Certification | ISO, CE |

| Color | White |

| Usage | Mall, Roofing and All Kinds of Underground Project |

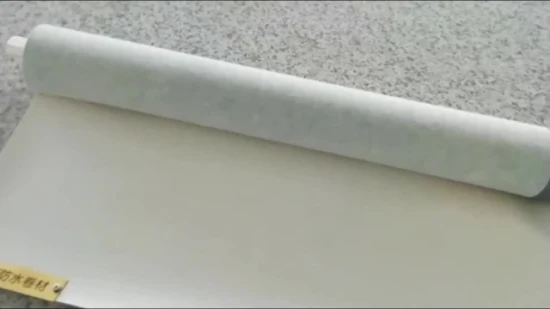

| Transport Package | Inner Tube +PP Woven Plastic Bag |

| Trademark | OTAi, OEM |

| Origin | Tianjin, China |

| Production Capacity | 15 Million Square Meters |

Product Description

Otai Polyvinyl Chloride (PVC) waterproofing membrane is a type of new high macro-molecular waterproofing membrane by adding plasticizer, filler, anti-oxidizer, ultraviolet light absorber and other auxiliaries with polyvinyl chloride resins as raw material.

| Thickness | 1.2mm /1.5mm/ 2.0mm |

| Length | 20m or customized |

| Width | 2m or customized |

| Types | Homogeneous, Reinforced, Fleece backed |

| Color | White or customized |

| Certificate | CE certificate, ISO9001/14001/45001 |

Characteristics

1. High tensile strength , good elongation , strong applicability for base expansion or cracking deformation .2. Large width ,high construction efficiency , small product consumption .3.Good diffusion of water vapor , easy discharge of condensate , easy discharge of moisture left in the substrate4. Root penetration resistance , chemical corrosion resistance and aging resistance ;5. maintain good flexibility even at -25ºC6.High Security without open flame installation7. It used for exposed ,service life 10 years ; if unexposed used , the service life can be 50-100 years .8. The artificial weathering time of Otai PVC is not less than 4100 hours.9. Anti-Wind reach 135 PSF

Physical Property

| NO. | Test Item | Index |

| H | L | P |

| 1 | The thickness of resin layer above the reinforcement fabric/mm ≥ | - | - | 0.4 |

| 2 | Tensile Property | Maximum Tension N/cm ≥ | - | 120 | 250 |

| Tensile Strength Mpa ≥ | 10.0 | - | - |

| Max Tension Elongation/ % ≥ | - | - | 15 |

| Breaking Elongation/ % ≥ | 200 | 150 | - |

| 3 | Heating treatment size change rate % ≤ | 2.0 | 1.0 | 0.5 |

| 4 | Low temperature bending | -25ºC no crack |

| 5 | Water impermeability | 0.3Mpa, 2h impermeable |

| 6 | Impact resistance | 0.5kg·m, impermeable |

| 7 | Anti-static load | - | - | 20kg impermeable |

| 8 | Seam peel strength N/mm ≥ | 4.0 | 4.0 | 3.0 |

| 9 | Right-angle tear strength N/mm ≥ | 50 | - | - |

| 10 | Trapezoid tear strength N ≥ | - | 150 | 250 |

| 11 | Water absorbing capability (70ºC, 168h)% ≤ | After soaking | 4.0 |

| after airing | -0.4 |

| 12 | Heat aging (115ºC) | Time/h | 672 |

| Appearance | No bubble, crack, delamination, bonding and holes |

| Max tensile retention % ≥ | - | 85 | 85 |

| Elongation retention % ≥ | 85 | - | - |

| Tensile strength (Max Tension) retention % ≥ | - | - | 80 |

| Breaking elongation retention/% ≥ | 80 | 80 | - |

| Cold bending | -20ºC no cracking |

| 13 | Chemical resistance | Appearance | No bubble, crack, delamination, bonding and holes |

| Max tensile retention % ≥ | - | 85 | 85 |

| Elongation retention % ≥ | 85 | - | - |

| Tensile strength (Max Tension) retention % ≥ | - | - | 80 |

| Breaking elongation retention/% ≥ | 80 | 80 | - |

| Cold bending | -20ºC no cracking |

| 14 | Artificial climate accelerating aging | Time/h | 1500 |

| Appearance | No bubble, crack, delamination, bonding and holes |

| Max tensile retention % ≥ | - | 85 | 85 |

| Elongation retention % ≥ | 85 | - | - |

| Tensile strength (Max Tension) retention % ≥ | - | - | 80 |

| Breaking elongation retention/% ≥ | 80 | 80 | - |

| Cold bending | -20ºC no cracking |

| Single-ply membrane artificial climate accelerating aging time is 2500h |

Applicable RangeSuitable for industrial and municipal construction exposed & unexposed roofs, garage roof, basement, subway, tunnel, caverns, bridge, landfills, sewage treatment pool and other underground waterproofing projects.Classic Projects ReferenceBangkok Airport TerminalThailand Power PlantNew Zealand East Garden Residential ProjectSouth Korean Daewoo Automobile FactoryUK Londo StadiumIrish Airport AnexMongolia GM PlantMongolia Biya Star HotelNational University of MongoliaPackaging & Shipping

| Port: | Tianjin Xingang Port |

| Shipping: | Support Sea freight |